Multi-purpose chamber furnace is one of the core and experienced AICHELIN products and with more than 100 years of history of providing high quality products to many internationally renowned companies. This line is for small and medium capacity, numerous types of components and a large variety of components. Ideal for high flexibility in different heat treatment processes.

more details

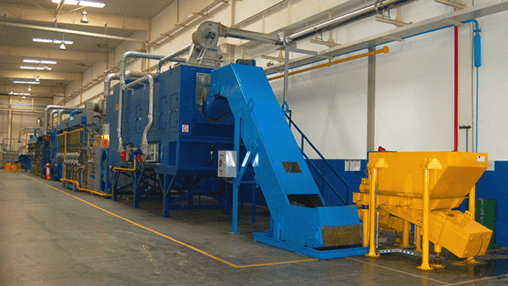

Pusher type furnaces for gas carburization are quite economical and energy saving due to their continuous operation and their high-performance output. With the upgrade of products, the degree of automation is getting higher and higher, and widely welcomed by users of large-scale continuous production industries such as automobiles, gears, bearings, etc. The double – row pusher type furnace can further obtain different carburizing depths in one furnace.

more details

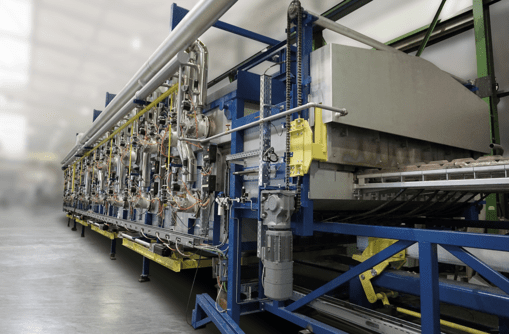

Aichelin Roller-Hearth Atmosphere Controlled furnace line is well used in he bearing industry, but also for various other parts. It usually divides into three types in accordance with the process requirements of the parts: typical annealing line; oil quenching line and salt quenching line.

more details

AICHELIN rotary hearth furnace is used for heating and quenching of spiral bevel gears, synchronizer gear sleeves, bearings and other parts in a large-scale protective atmosphere. Due to small space taken up, high continuous production capacity, one furnace door for loading and discharging, and the multi-layer traying is used to realize gas carburization, carbonitriding, clutch diaphragm hardening and bearing rings as well as other components Bainite isothermal quenching.

more details

The ring hearth furnace is self-developed by AICHELIN. It combines the advantages of a rotary hearth furnace and a pusher furnace. The design allows a separation of heating, carburizing and diffusion zone so that different carbon levels and temperature profiles can be processed nearly independently in the different chambers. It is especially suitable for the press quenching and quenching heat treatment processes of bevel gears, driving gear shafts and other parts in the automobile industry.

more details

AICHELIN pit furnace is applicable for gas carburizing, carbonitriding, gas nitriding, nitrocarburizing, hardening and tempering, annealing processes of many kinds of large parts.

more details

This line is designed for nitriding and nitrocarburizing of gears, tools, and molds. The result of this heat treatment is a wear resisting oxidation layer which is like hard chrome plating and shows a comparably good corrosion resistance. A good appearance quality, uniform hardness, and small deformation of nitride parts.

more details

This line is designed for pre-heat treatment of large capacity of large-scales parts for wind-energy industry. It removed trays which used to be repeatedly heated together with parts and cooled, so the energy saving is very remarkable.

more details

此生产线适用于大批量的小型轴承滚动体、紧固件、小轴及小环形零件的光亮淬火、调质处理及浅层渗碳零件的淬火、回火等热处理。

more details

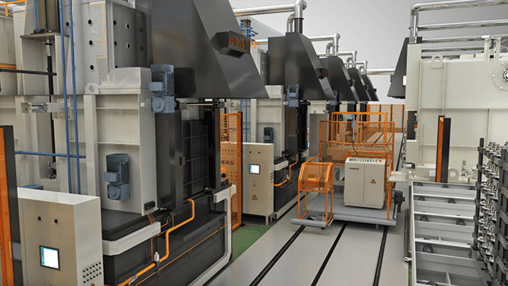

This furnace is used for vacuum heating + gas quenching/ Annealing/Tempering.

more details

Hot forming of car body parts in the automotive industry sets new standards for component properties in series production. Complex components can be produced with high stability and optimized formability at will.

more details